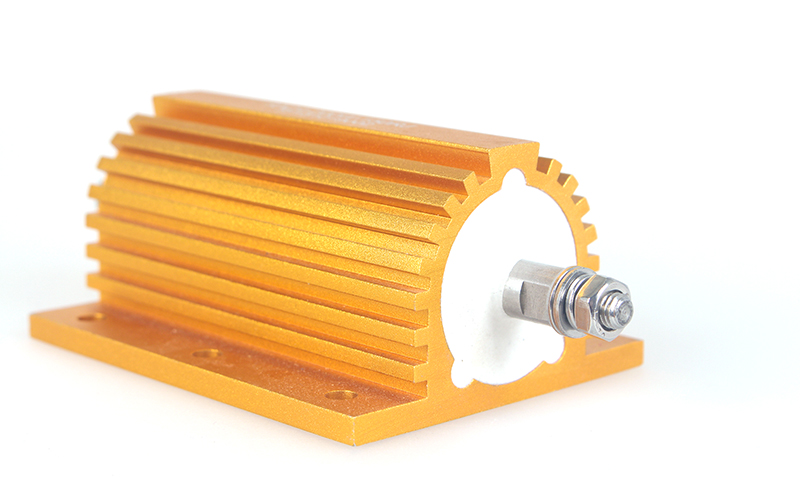

Product features:

1. Small size and high power

2. Sturdy structure and high stability

3. Aluminum shell for heat dissipation, suitable for installation of heat dissipation plates

4. Silicon copper film compression molding with good insulation performance

5. Meets lead-free/RoHS requirements

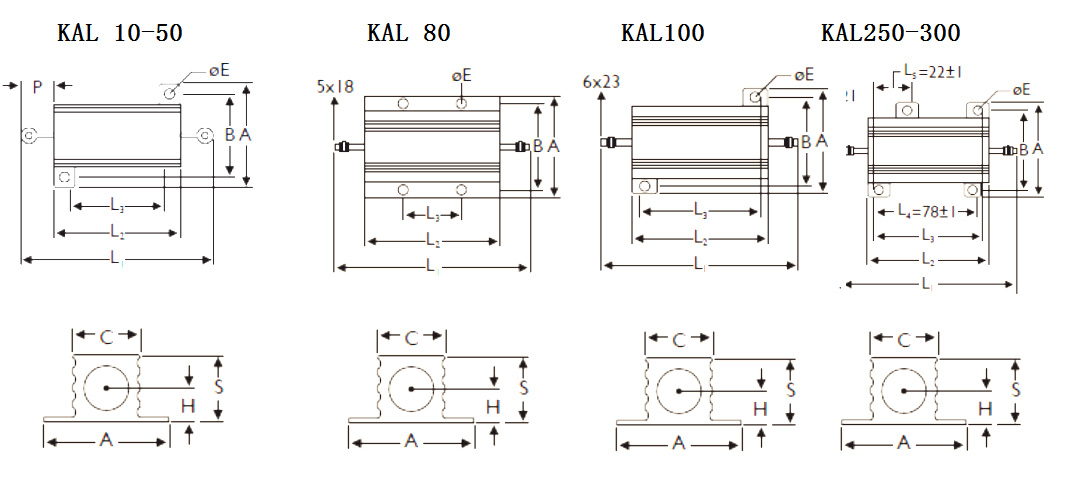

| Category Style | Dimensions unit: mm | ||||||||

| L1 ± 2 | L2 ± 1 | L3 ± 1 | A ± 1 | B ± 1 | C ± 1 | E ± 0.3 | S ± 1 | H ± 0.5 | |

| KAL 10 | 32 | 19 | 14 | 20 | 15.5 | 10.5 | 2 | 10 | 5 |

| KAL 25 | 47 | 27 | 18 | 27 | 19 | 15 | 3.2 | 15.5 | 7 |

| KAL 50 | 70 | 50 | 39 | 29 | 21 | 15 | 3.2 | 15.5 | 7 |

| KAL 80 | 102 | 66 | 35 | 47 | 37 | 28 | 4.5 | 25 | 12 |

| KAL 100 | 135 | 89 | 69 | 70 | 48 | 46 | 5 | 44.5 | 19.5 |

| KAL 250 | 155 | 114 | 98 | 77 | 64 | 53 | 5 | 55.5 | 25 |

| KAL 300 | 155 | 114 | 98 | 77 | 64 | 53 | 5 | 55.5 | 25 |

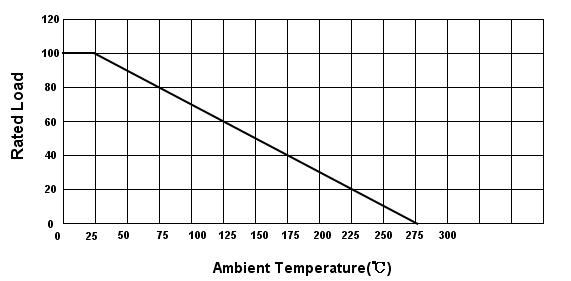

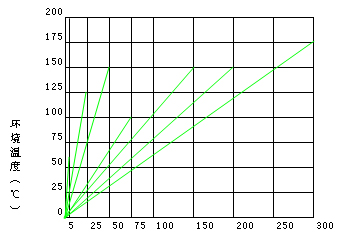

Power attenuation curve and temperature rise curve:

Power attenuation curve:

Temperature rise curve:

Technical description:

| Category Style | Power Rating | Resistance range (Ω) | Maximum working voltage MWV (V) | Heat dissipation plate area | Weight (g) Weight |

||||

| With heat dissipation plate | Without heat dissipation plate | KAL | NKAL (no sensation) | KAL | NKAL (no sensation) | Surface area (cm2) | Thickness (mm) | ||

| KAL 10 | 10 | 8 | 0.02-6K | 0.03-2.3K | 245 | 180 | 415 | 1 | 6 |

| KAL 25 | 25 | 13 | 0.012-15K | 0.02-5.5K | 500 | 300 | 535 | 1 | 11 |

| KAL 50 | 50 | 10 | 0.01-40K | 0.02-12K | 1300 | 600 | 995 | 1 | 30 |

| KAL 80 | 80 | 45 | 0.1-3.0K | 0.1-3.0K | 1500 | 1000 | 995 | 3 | 90 |

| KAL 100 | 100 | 50 | 0.4-50K | 0.12-25K | 1900 | 1340 | 995 | 3 | 160 |

| KAL 250 | 250 | 60 | 0.6-80K | 0.15-40K | 2500 | 1750 | 4765 | 3 | 480 |

| KAL 300 | 300 | 70 | 0.6-90K | 0.15-50K | 2500 | 1750 | 4765 | 3 | 550 |

Main performance:

Reference standard: JIS-C-5202

| project Items |

Standard value Standard |

test method Test Methods |

|||||||

| Short term overload Short time overload |

± 1% | 2.5 times rated power/5 seconds 2.5 times power/5 seconds |

|||||||

| temperature coefficient Temperature Coefficient |

± 200 PPM/℃ | Experimental temperature: Room temperature 100 ℃ Test temperature: Indoors Temperature. 100 ℃ |

|||||||

| Heat resistance Resistance to solver head |

± 1% | Soldering temperature: 350 ± 10 ℃, time: 3 seconds Solder Temperature: 350 ± 10 ℃, time: 3 seconds |

|||||||

| Voltage withstand Dielectric with standing voltage |

No burning or insulation damage No breakdown or flashover |

Apply a DC voltage of 500V for 1 minute 500V for 60 seconds |

|||||||

| Moisture resistance load Humidity Load Life |

± 0.5% | Temperature: 40 ± 2 ℃, relative humidity: 90-95%, 1 time the rated working voltage, time 1000 hours (1.5 hours on and 0.5 hours off) Rated voltage 1.5hr ON, 0.5hr OFF at 40 ± 2 ℃, 90-95&RH for 1000hr |

|||||||

| Load life Load Life |

± 2.0% | Temperature: 25 ℃, 1 time the rated working voltage, time 1000 hours (1.5 hours on and 0.5 hours off) Rated voltage 1.5hr ON, 0.5hr OFF at 25 ℃ for 1000hr |

|||||||

| Solderability Solderability |

More than 95% of the tin eating area At least 95% coverage |

Soldering temperature: 235 ± 5 ℃, time: 2 ± 0.5 seconds 235 ± 5 ℃ for 2 ± 0.5 seconds |

|||||||

Tel

Service

TOP